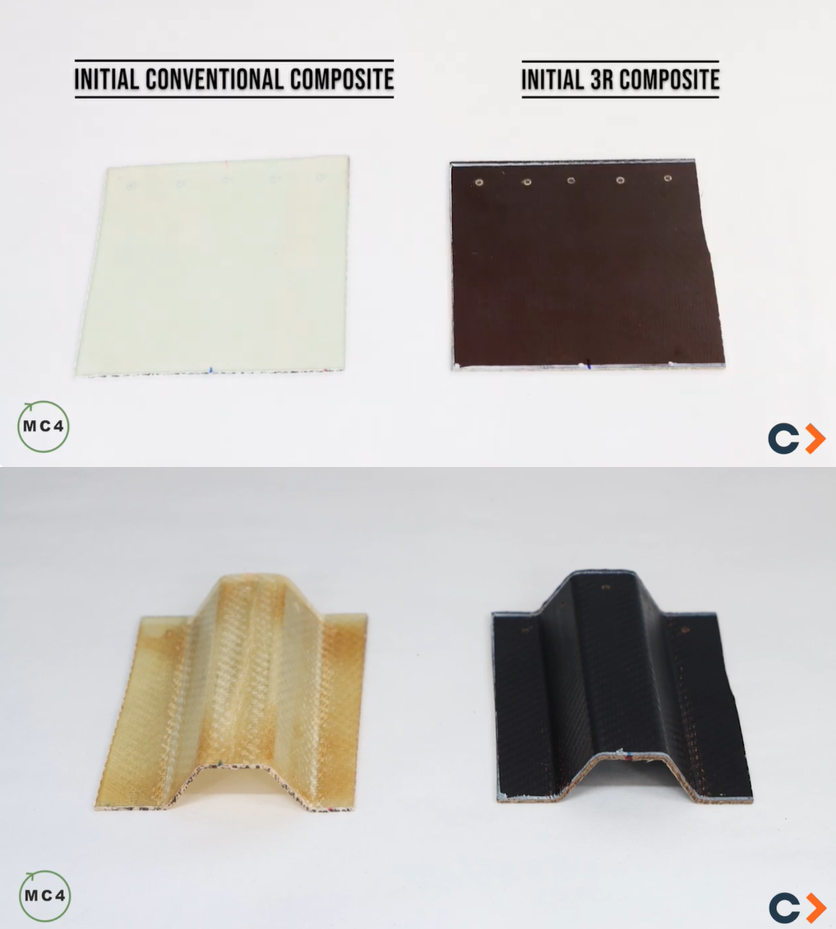

CIDETEC, one of the MC4 project partners is currently doing tests on the reshaping of composites made with their newly developed vitrimer 3R epoxy resin. Unlike conventional epoxy resins that are thermosets and therefore can’t be reused without being damaged and losing in properties, the 3R can be reshaped. Indeed, it is based on dynamic covalent chemistry for the direct re-use of the composite materials. CIDETEC uploaded the following video in their YouTube channel to present their first results:

MC4 – CIDETEC Surface Engineering (youtube.com)

In the video, a conventional composite with an epoxy matrix and a 3R composite were reshaped using a hot press of 180°C under a pressure of 60 bars for 40 minutes. The results display that the conventional composite, once reshaped is damaged contrary to the 3R one that looks as good as new.

To learn more about the work CIDETEC is doing you can follow these links:

Article in Polymers Journal « Analysis on the effect of network structure and disulfide concentration on vitrimer properties” : https://doi.org/10.3390/polym15204123

Linkedin: (2) CIDETEC : Présentation | LinkedIn

Website : HOME | Cidetec

“Funded by the European Union. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or the European Health and Digital Executive Agency. Neither the European Union nor the granting authority can be held responsible for them.”