An important aspect of the MC4 project is the investigation and development of methods and technologies for the efficient and reliable sorting of carbon and glass fibre composite materials at the end of their service life.

Why is that? Because the chemical recycling processes for such composite materials depend heavily on the resin system of the materials. It is therefore important to distinguish and classify composite parts according to their resin system so that they can be directed to the appropriate recycling route.

The basic requirement for reliable mechanical sorting is reliable material identification. To avoid altering the materials, a non-contact and non-destructive analysis is needed. In addition, the method must be fast (for use in an industrial sorting plant) and easy to automate (to save manpower). This explains the preference for optical, especially spectroscopic techniques.

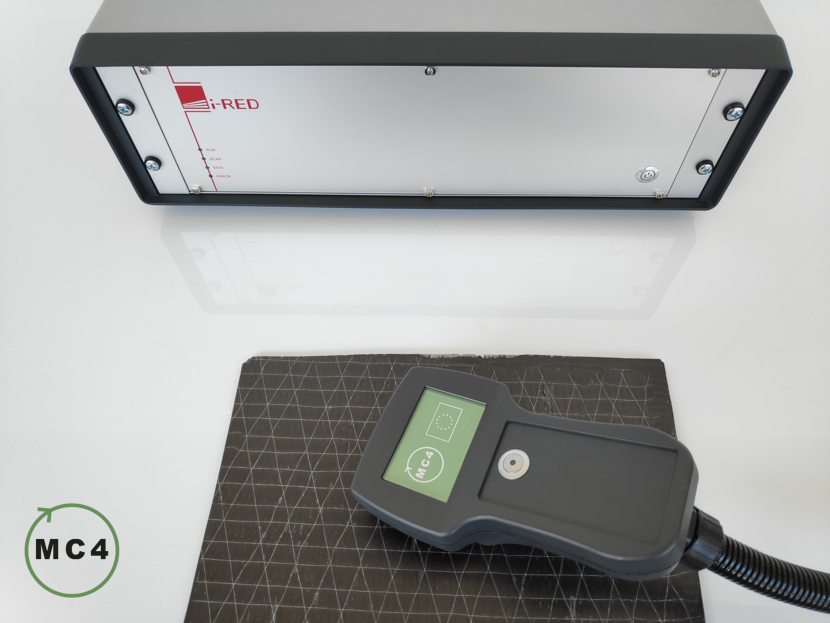

The project partner who is in charge of this topic is i-RED Infrarot Systeme GmbH, located in Linz, Austria. The company produces spectroscopic real-time monitoring solutions for the control and optimization of industrial production, recovery, and recycling processes.

i-RED was able to show that near-infrared (NIR) spectroscopy is a suitable approach for detecting the resin system of both carbon and glass fibre composite waste.

With carbon fibre materials, the challenge was to obtain sufficient signal / information from the waste parts, as such materials are black and therefore reflect very little light. However, with an optimized reflection optics it was, for example, possible to discriminate materials with epoxy-amine system from materials with epoxy-anhydride system. This is important for subsequent chemical recycling using a process developed by GAIKER as part of the project.

In the case of glass fibre composites, it has been shown, among other things, that parts made from a specific epoxy vitrimer (“3R resin”, developed by CIDETEC) can be distinguished from parts with other resin system. The significance of this result is explained by the fact that only composites fabricated with vitrimers can be reshaped at the end of their service life and processed into new parts (by applying heat and pressure).

Another important issue concerns the large-scale implementation of the NIR method in a mechanical sorting plant (e.g. above a conveyor belt): the results of i-RED show that identifying the resin system of fibre-reinforced composites requires (multi-)point measurements using a high-resolution NIR process spectrometer that covers the entire NIR spectral range. This can, for example, be realised using a delta robot with mounted NIR reflection optics in conjunction with a camera system to determine the position of the waste on the conveyor belt.

If there is one takeaway from the encouraging results of i-RED, it is that near-infrared spectroscopy has great potential to make the world more circular and environmentally friendly.

For more information on the work i-RED is doing you can visit the following links:

Webpage: Spektroskopische Prozessüberwachung | i-RED

Linkedin: (1) i-RED Infrarot Systeme GmbH : Présentation | LinkedIn

“Funded by the European Union. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or the European Health and Digital Executive Agency. Neither the European Union nor the granting authority can be held responsible for them.”